Looks like we've sold out of this product.

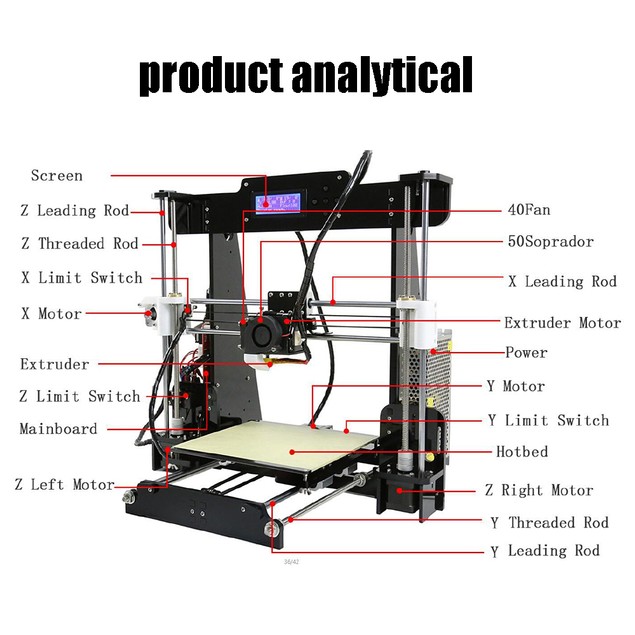

Anet A8 High Precision Desktop 3D Printer Kits

Log in To Earn 0 points for this purchase!

Log in To Earn 0 points for this purchase!

Estimated delivery Feb 16 - Feb 20 (Why?)

This ships from an international warehouse, please allow extra time for the product to reach you.

This deal is already so low, it isn’t eligible for additional discounts/coupons.

High cost-effective DIY 3D printer, it features 2004 LCD screen, 5 keys for easy operation, support SD card and off-line printing, customized MK8 nozzle, sturdy and compact lead screw, advanced and high-speed motor, updated sophisticated mainboard, superior power supply system, work well with many types of 3D filament, such as ABS, PLA, HIP, PP and Nylon etc. Widely applied to many field, printing 3D toys, teaching equipment, and other technological devices, great for stimulating users’ creativity and inspiration and realizing their ideal. Assembling DIY 3D printer is a pretty fun experience, all of the kits are produced under the strict observation, high quality products at a reasonable price, this printer is highly recommended for beginner and various 3D works lovers with abundant imagination.

Features:

- 2004 LCD screen, English interface, 5 keys for easy operation, support SD card and off-line printing.

- Customized MK8 nozzle with sophisticated technology to produce smooth filaments fluently.

- T-shape lead screw, high quality stainless steel, more durable and sturdy for use.

- Advanced and high-speed motor, continue to prolonged work hours for greatly improved the working efficiency.

- Updated sophisticated mainboard, supporting multi-function, higher accuracy.

- Superior power supply system for safely using, 240W, 110V-240V.

- Heated hotbed and nozzle with wide range temperature adjustments allow the printer to compatible with many 3D filament types, such as ABS, PLA, HIP, PP and Nylon etc.

- 10 meters 3D filaments, SD card with electronic installation manual, card reader, other necessary parts and tools for assembling are included.

- Wide application for printing 3D toys, teaching equipment, and other technological devices, great for stimulate users’ creativity and inspiration and realize their ideal.

Specifications:

- Screen: LCD2004

- Frame Material: Acrylic

- Hotbed Material: Aluminum Alloy

- Nozzle Quantity: 1

- Printing color: Single

- Printable Material: ABS/PLA/HIP/PRTG/TPU/Wood/Nylon/PP etc

- Filament Diameter: 1.75mm

- Plug: US

- Voltage: 110-220V

- Current: 20A

- Power: 240W

- Item Size(Assembled): 50 * 45 * 40cm / 19.7 * 17.7 * 15.7in

- Item Weight: 8Kg / 17.6Lbs

- Package Size: 51 * 31 * 21cm / 20.1 * 12.2 * 8.3in

- Package Weight: 9.5Kg / 20.9Lbs

Technological Parameter:

- Max. Printer Size: 220 * 220 * 240mm

- Printer Speed: 10-120mm/s

- Nozzle Diameter: 0.4mm

- Layer Thickness: 0.1-0.3mm

- Printing Accuracy: 0.12mm

- XY Axis Accuracy: 0.015mm

- Z Axis Accuracy: 0.005mm

- Nozzle Temperature: Max. 260°C

- Hot Bed Temperature: 50-100°C

- Recommend ABS Setting: Nozzle: 230 °C Hotbed: 80 °C

- Recommend PLA Setting: Nozzle: 210 °C Hotbed: 50 °C

Software Requirement:

- Operating System: Windows XP/Win7/Win8/Mac/Linux

- Printing Software: Cura / Repetier-host

- File Type: .STL / .OBJ / G-code

- Offline: Yes

Package List:

- 1 * Set DIY 3D Printer Kit

- 1 * SD Card(Installation Instruction Included)

- 1 * Card Reader

- 4 * Hex Wrench

- 1 * Open Spanner

- 1 * Nipper

- 1 * Screwdriver

- 1 * 10m Filament

Note:

- Please check the parts number before assembling.

- The filament of red and the models shown in the picture not included, but 10m white filament attached to the package.

- The installation instruction, print model STL, software, test file GCODE and tool list pictures are included in the free SD card.

Frequently Asked Questions:

Q1: How to deal with problem of there is no display, and after you press the reset button, the indicator D1 does not light and with no backlit?

A1、Please check the power line and screen connecting cable, and whether the power supply is working normally.

Q2: When the screen just display squares, and the the indicator D1 does not light after you press the reset button, How to deal with?

A2、We will provide you software and you can solve the question by reinstalling the system software.

Q3: What can you do when there is no backlit, or it have backlit and squares, the indicator D1 light after you pressed the reset button?

A3、You just need to check whether it is right connection between screen and mainboard, and the contact is well or not.

Q4: How to deal with the condition that the screen with backlit but no other display, the indicator D1 light after you pressed the reset button?

A4、Swirling the “R7” on mainboard by screwdriver untill the screen display squares, and then press the reset button on mainboard.

Q5: How to do with that the 4 motors do not running?

A5、The worry plug of power supply leading the IC burning out. Checking measure: Step 1, hand control the motor, and find out which one have problem, choose “Position” and control X axis, Y axis, Z axis and the extruder motor independently; Step 2, exchange the problem motor under the control of other axis, for example, the X motor with problem, exchange the motor place of X with Y, choose “Position” to control X axis and Y axis, eliminating the problem motor by observing whether the motor is working normally.

Q6: No option “Print file” after installed SD card, How to do?

A6、Step1, checking that if the SD card can be recognized by the computer, and whether it can store file; Step2, be sure that it is right way to install the SD card by install it repeatedly, if the card can’t be recognized, please replace the card, if there is still no “Print file” option after everything is fine, you should change the mainboard.

Q7: How to solve the problem of leaking filament?

A7、Please rotating well the nozzle and tube, if it doesn’t working, please change the nozzle or tube.

Q8: The way to deal with the problem of the printing model can’t paste on the hotbed.

A8: 1、Be sure that the hotbed with crepe paper or high-temperature masking tape; 2、Checking the hotbed temperature fit for the printing filament, such as, the PLA filament suits the temperature around 50 °C, and the ABS filament suits the temperature 70-90 °C; 3、The height problem of hotbed, you can adjust to a proper hotbed height as follow: Close the motor, after the machine parameter turn to zero, checking the four corners height of hotbed by putting a A4 paper on the hotbed and moving the hotbed and nozzle horizontally, and then adjust the screw of hotbed, it gets suitable height when the nozzle past the paper with resistance.

Q9: The resolution for you can’t take the big size print model out.

A9: Try to take it out as the printer still preheating, even you can use tool, such as blade or shovel. Please setting the attachment tape “Brim” for you convenience.

Q10: How to deal with it when the nozzle is clogged?

A10、Unscrewing the screws and take down the fan, and clamp fetch the broken filament out with nipper, push out and melt the rest broken filament that can’t be taken out by filament or inner hexagonal wrench, if it still no effects, please change the tube or nozzle.

- 30 day warranty

- New

- Free Shipping!

- Ships from international warehouse

- Estimated delivery Feb 16 - Feb 20

- Returns available within 15 days

- Ships to U.S. (No AK/HI, No P.O. Boxes, and No Military Addresses)

Our awesome customer service department is ready for your questions! Although we are a small company (8 of us total), we will do everything we can to answer your questions and take care of any problems.

Contact UsSubscribe and we'll give you first dibs on all daily deals and sales. We’ll also send coupons for even further discounts.